Offset printing ink for food packaging

The graphic part of lithography (i.e. the oil-absorbing part) and the non-graphic part (i.e., hydrophilic oil drainage lang V) are on the same plate P plane. Using the oil water exclusion principle, through special processing, make the plate parts selective wetting ability a blank part to hydrophilic oil resistance, and figure form part of the oil and water resistance, printing plate coated with education version water first, make the gap of the plate are water embellish W, the ra form part of the oil, no water, and then coated ink, make graphics part of lis.

相關資訊

Offset printing ink for food packaging

The graphic part of lithography (i.e. the oil-absorbing part) and the non-graphic part (i.e., hydrophilic oil drainage lang V) are on the same plate P plane. Using the oil water exclusion principle, through special processing, make the plate parts selective wetting ability a blank part to hydrophilic oil resistance, and figure form part of the oil and water resistance, printing plate coated with education version water first, make the gap of the plate are water embellish W, the ra form part of the oil, no water, and then coated ink, make graphics part of lis.

相關資訊

同類文章排行

- 餅幹甜品食品該用什麽材質包裝方案呢

- 複合袋塑料包裝袋各種材質的厚度和密度

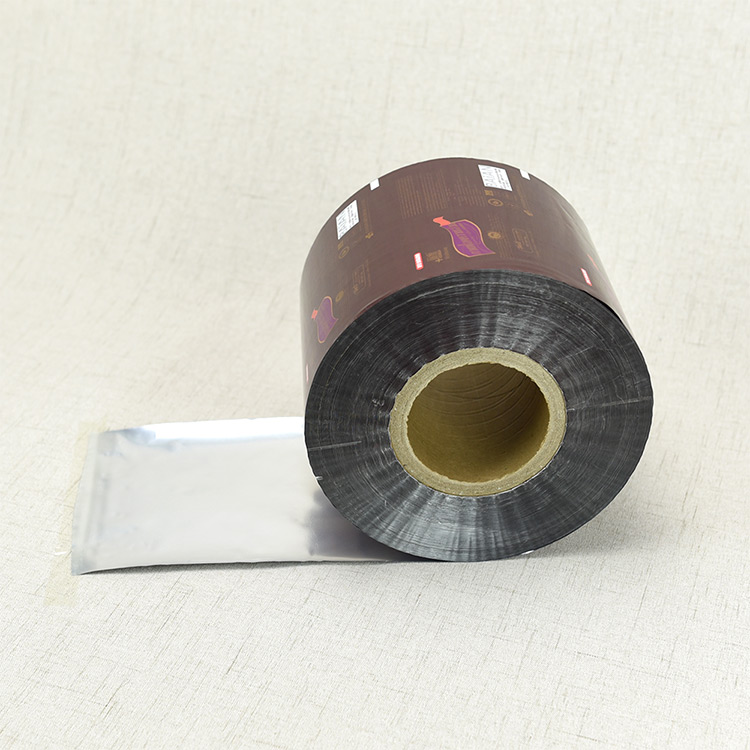

- 鋁箔複合袋的結構和應用

- 星空游戏网官网的塗布複合工藝

- 食品袋生產過程中粘結劑的配製及用途

- 食品袋所用尼龍材質的特點

- 星空游戏网官网印刷過程中的連接料

- Offset printing ink for food packaging

- 塑料包裝袋的抗靜電劑

- 食品袋廠家星空游戏登陆平台下载链接膠袋國慶放假通知

最新資訊文章

您的瀏覽曆史

電話:150-1714-8657 / 0769-87333767-225

電話:150-1714-8657 / 0769-87333767-225 傳真:0769-87331713

傳真:0769-87331713

Email:

Email: 公司地址:廣東省東莞市清溪鎮廈坭村清塘路46號

公司地址:廣東省東莞市清溪鎮廈坭村清塘路46號